As legislation evolves, ensuring medical equipment traceability has become a critical requirement. Key deadlines mandate that traceability must be implemented through laser marking for the following devices:

- Class 3 and Implantable Devices: Required by May 2023

- Class 2a and 2b Devices and Instruments: Required by May 2025

- Class 1 Devices and Instruments: Required by May 2027

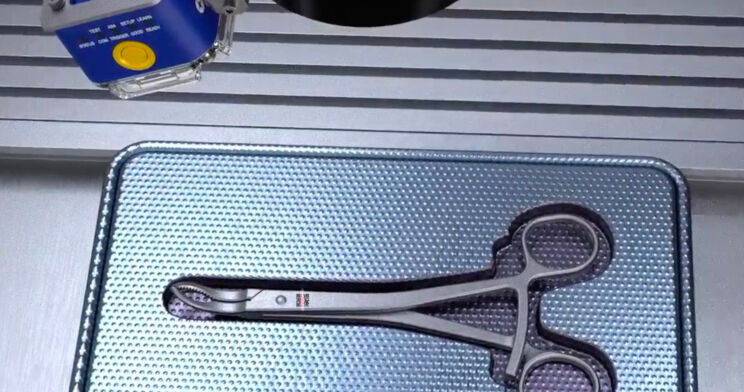

Laser marking technology provides precise and durable identification for surgical instruments, utilising GS1 standards and 2D DataMatrix codes. This innovative solution enhances instrument tracking and traceability throughout critical stages, including washing, disinfection, packing, and sterilisation in hospital decontamination units.

By integrating GS1-compliant laser marking, each instrument is assigned a unique GS1 GTIN and UDI code, ensuring site-specific identification that meets industry standards. This technology improves inventory management, boosts operational efficiency, and supports regulatory compliance for surgical instrument identification systems.

Our laser marking systems offer exceptional durability and cost-effectiveness, requiring no ongoing consumables. Independent testing confirms that the process maintains the passive protective layer of metals, making it safe for stainless steel, titanium, and plastic surgical instruments without compromising their integrity.

Enhance your hospital’s decontamination processes with advanced laser marking technology designed for precision, reliability, and compliance.

Why use Sciamed's technology?

Our technology benefits from:

- GS1 Standard Compliance for global traceability

- UDI Code Integration for unique and site-specific identification

- Compatibility with stainless steel, titanium, and plastic materials

- Sustainable operation with no ongoing consumable costs

- Maintains metal integrity while ensuring long-lasting mark

Lophius Newland Scanners (Corded and Cordless DPM)

Efficiently read and verify laser markings with Lophius Newland scanners. These tools are designed for high precision and are perfect for reading Direct Part Marking (DPM) codes on various surfaces.

- Corded Scanners: Reliable and consistent for stationary setups.

- Cordless Scanners: Flexible and mobile for dynamic environments.

Surgiscan Ultra Lite

Introducing the Surgiscan Ultra Lite—a lightweight, ergonomic scanning solution designed for medical environments.

- Simplifies tracking surgical instruments.

- Compact and easy to use, even in the busiest settings.

Learn more about how Surgiscan Ultra Lite supports surgical teams

How we've helped other people...

In collaboration with NHS Tayside, Sciamed implemented a comprehensive laser marking solution to enhance surgical instrument traceability.

By integrating advanced laser marking technologies and precise GS1-compliant identification, we achieved:

- Improved inventory management

- Enhanced patient safety

- Long-term cost savings

Why choose Sciamed?

- Experience You Can Trust: With years of industry expertise, we understand your unique needs.

- Proven Results: Our international solutions deliver measurable success.

- Advanced Technology: We provide cutting-edge tools like the Lophius scanners and Surgiscan Ultra Lite.

- Commitment to Safety: From laser safety glasses to fume extraction, we prioritise your safety.

- Ongoing Support: With annual maintenance and performance testing, we’re here for the long term.

Laser Marking Solutions

Boost Productivity

By identifying each instrument with a permanent mark, time spent affixing labels or identifying un-tagged instruments is saved. Training is given to your team who can perform the marking on-site.

Increase Accuracy

Each surgical instrument is marked with a permanent high-quality and high precision barcode which ensures every step in the instruments life cycle can be tracked.

Stay Compliant

Healthcare providers and manufactures are now required to track and trace all medical devices. 2D Datamatrix codes that incorporate UDI (Unique Device Identification) which comply with GS1 standard are used to minimise the code size, whilst maintaining readability.

Simplicity

Compared to affixing a label or tag to the device, laser marking only has to be performed once. No additional steps or consumables are required.

Frequently Asked Questions

Why laser marking?

New regulations dictate that certain medical devices must be marked with a unique device identification code. Laser marking is a cost-effective and reliable solution that marks each piece of surgical equipment with a GS1 standard, 2D Datamatrix code which does not deteriorate during the decontamination process.

Label-based identification system requires labels to be replaced every two years.

How does it work?

The system uses a short pulse laser to permanently mark the instrument with a GS1, 2D Datamatrix code leaving a smooth finish which is critical for the healthcare environment. Once marked it allows the item to be tracked and traced throughout the cleaning, packing and disinfection process.

The laser marking process has been found to not affect the passive protective layer of the metal ensuring the quality of the instrument material does not deteriorate.

What are the benefits?

- No ongoing requirement for consumables

- Permanent marking is essential in medical devices as it provides traceability

- The laser mark is a permanent mark on the surface of the instrument which does not create a crevice, where dirt or debris could collect

- Marking instruments is a quick and simple non-contact marking process

What material can the laser be applied on?

The system is able to mark a GS1 Unique Identifier code that is site-specific on a wide variety of materials including Stainless Steel, Anodised Aluminium, Titanium, Plastics and many more.

How do I find out more?

Get in touch for a free demonstration of our laser marking system or if you have any specific requirements call 01975 564111 or email sales@sciamed.co.uk