Discover the Future of Laser Marking – Join Us on 19th March

We are thrilled to be showcasing our innovative laser marking solutions at DeconUK 2025, the premier event for decontamination professionals and industries looking to streamline their processes with advanced marking tools.

Join us at Stand 17 on Wednesday, 19th March, and explore how our state-of-the-art laser marking tools can transform your workflow with precision, durability, and speed.

Book a demoEnhance your hospital’s decontamination processes with advanced laser marking technology designed for precision, reliability, and compliance.

Why use Sciamed's technology?

Our technology benefits from:

- GS1 Standard Compliance for global traceability

- UDI Code Integration for unique and site-specific identification

- Compatibility with stainless steel, titanium, and plastic materials

- Sustainable operation with no ongoing consumable costs

- Maintains metal integrity while ensuring long-lasting mark

How we've helped our customers...

In collaboration with NHS Tayside, Sciamed implemented a comprehensive laser marking solution to enhance surgical instrument traceability.

By integrating advanced laser marking technologies and precise GS1-compliant identification, we achieved:

- Improved inventory management

- Enhanced patient safety

- Long-term cost savings

Why choose Sciamed?

- Experience You Can Trust: With years of industry expertise, we understand your unique needs.

- Proven Results: Our international solutions deliver measurable success.

- Advanced Technology: We provide cutting-edge tools like the Lophius scanners and Surgiscan Ultra Lite.

- Commitment to Safety: From laser safety glasses to fume extraction, we prioritise your safety.

- Ongoing Support: With annual maintenance and performance testing, we’re here for the long term.

Lophius Newland Scanners (Corded and Cordless DPM)

Efficiently read and verify laser markings with Lophius Newland scanners. These tools are designed for high precision and are perfect for reading Direct Part Marking (DPM) codes on various surfaces.

- Corded Scanners: Reliable and consistent for stationary setups.

- Cordless Scanners: Flexible and mobile for dynamic environments.

Surgiscan Ultra Lite

Introducing the Surgiscan Ultra Lite—a lightweight, ergonomic scanning solution designed for medical environments.

- Simplifies tracking surgical instruments.

- Compact and easy to use, even in the busiest settings.

Learn more about how Surgiscan Ultra Lite supports surgical teams

Can’t Attend DeconUK? We’ll Come to You!

If you can’t make it to DeconUK, don’t worry! Our team of experts can visit your facility to provide an on-site demo tailored to your specific needs. This allows your entire team, including key decision-makers, to see the technology in action and ask questions in the comfort of your workspace. We’ll bring the same expertise and hands-on demonstrations directly to you, making it easier than ever to explore the benefits of laser marking for your business.

Schedule an on-site demo

Frequently Asked Questions

Why laser marking?

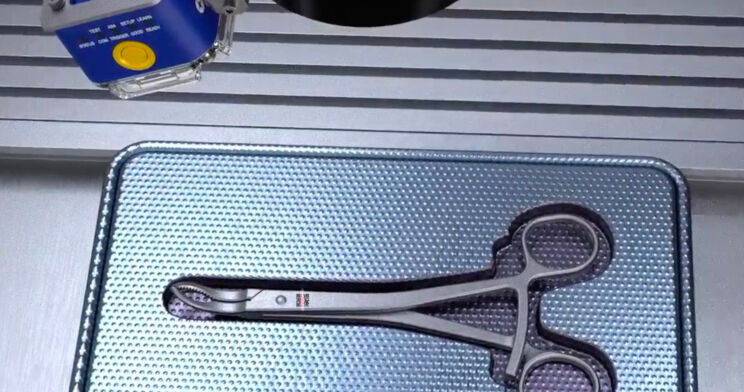

New regulations dictate that certain medical devices must be marked with a unique device identification code. Laser marking is a cost-effective and reliable solution that marks each piece of surgical equipment with a GS1 standard, 2D Datamatrix code which does not deteriorate during the decontamination process.

Label-based identification system requires labels to be replaced every two years.

How does it work?

The system uses a short pulse laser to permanently mark the instrument with a GS1, 2D Datamatrix code leaving a smooth finish which is critical for the healthcare environment. Once marked it allows the item to be tracked and traced throughout the cleaning, packing and disinfection process.

The laser marking process has been found to not affect the passive protective layer of the metal ensuring the quality of the instrument material does not deteriorate.

What are the benefits?

- No ongoing requirement for consumables

- Permanent marking is essential in medical devices as it provides traceability

- The laser mark is a permanent mark on the surface of the instrument which does not create a crevice, where dirt or debris could collect

- Marking instruments is a quick and simple non-contact marking process

What material can the laser be applied on?

The system is able to mark a GS1 Unique Identifier code that is site-specific on a wide variety of materials including Stainless Steel, Anodised Aluminium, Titanium, Plastics and many more.

How do I find out more?

Get in touch for a free demonstration of our laser marking system or if you have any specific requirements call 01975 564111 or email sales@sciamed.co.uk